-

- Abundante

- Adquirentes de pagos

- Ajustes

- Analítica

- Citas en línea

- Comercio Electrónico del Sitio Web de Odoo

- Configuración el Sitio Web de Comercio Electónnico

- Diseñe la Página de Su Sitio Web

- Gestión de Productos

- Gestión de Varios Idiomas

- Grupos

- Herramientas de fragmento

- Lista de precios

- Listado de productos

- Métodos de envío

- Múltiples compañías

- Múltiples sitios web

- Operaciones de blog en backd

- Pedido

- Personalización de la Página del Catálogo de productos

- Personalización del catálogo de productos

- Personalizar el menú y las apariencias

- Porcos

- Programas de cupón y promoción

- Publicar contenido específico para el sitio web

- RedirracionAmiento

- Salas de chat

- Sesión de Productos en la PESTAÑA CONFIGURACIÓN

- Sitio Web

- Tablero de Comercio Electrónico

- Tarjeta de Regalo

- Twitter Wall

- Visitantes

- Vistas de la Página

-

- Activo

- Adquirentes de pagos

- Biblioteca de contabilidad

- Catálogo de cuentas

- Conabilidad miscelána

- Configuración de Datos Bancario

- Contabilidad

- Contábilidad analíta

- Diario

- Estados de Cuenta Bancario

- Factura de Clientes al Pago

- Fechas de Bloqueo

- Fiscales de posiciones

- Gastos de Empleados

- Informa de de Socios

- Informa de seguimiento

- Informa en contabilidad

- Ingresos y Gastos Diferidos

- Mandatos de débito directo

- Notas de Crédito

- Pagos

- Pagos por lotes

- Presupuesto

- Reconciliatura

- Redondeo en efectivo

- Tablero de contabilidad

- Tipos de contabilidad

- Transferencias automáticas

- Términos de Pago

-

- Abundante

- Adquisico de Plomo

- CREACIÓN DE COTIZACIONES DE VENTAS

- CRM

- Caracteríssticas de Odoo 15 CRM

- Convertir LOS Cables en Oportunidades

- Cómo Odoo CRM Gestiona Las Oportunidades Perdidas

- FluJo de trabajo general de Odoo CRM

- Formulario de generación de plomo múltiples fuentes

- Funcionando -Con Clientes Potenciales

- Manejo de Liderazgo

- Nuevas Opciones en la ventana de configuración de Odoo 15

-

- Análisis de producción

- CREANDO CENTROS DE TRABAJO

- Fabricación

- Facturas de materiales

- Gestión de Chatarra

- Gestión de Mantenimiento

- Gestión de órdenes para no consultor

- Informe General de Efectividad del Equipo

- Pedidos de Fabricación

- Planificación de Pedidos Laborales por producción

- Planificación de órdenes de Trabajo por WorkCenter

- Programa de producció Maestra

- Órdenes de Trabajo

-

- Abundante

- Ajustes de Inventario

- Anuncios

- CARACTERÍSTICAS DEL MÓDULO DE INVENTARIO DE ODOO

- Categorizacia de productos

- Categorías de Almacenamiento

- Configuración del producto

- Confirmación de SMS en la Entrega

- Confirmación por Correo Electrónico en la Entrega

- Costos de Aterrizaje

- Empaquetado del producto

- Entrega

- Entregar Paquetes

- Estategias de Eliminación

- Gestión de Almacenes

- Gestión de Chatarra

- Integrando el Remitente de Terceros en Odoo

- Inventario

- Operaciones de inventario

- Planificadores

- Reglas de Caída

- Reglas y rutas

- Tiempos de Programació

- Trazabilidad del Producto

- Ubicacia

- Unidad de Medida

- Variantes de productos

-

- APEGO Salarial

- Abundante

- Configuración

- Contratos

- Entradas de Trabajo

- Estructuras salariales

- Información personal

- Nómina de Odoo

- OTROS TIPOS DE ENTRADA

- Parámetros de la regla salarial

- Reanudar

- Salarios de reglas

- Salpicaduras

- Tablero

- Tiempos de Trabajo

- Tipo de estructura salarial

- Tipos de Entrada de Trabajo

- Ventajas

Manufacturing- Odoo 15 Enterprise Book

Bills of Materials

La factura de materiales es el registro de las materias primas o los componentes utilizados en la fabricación del producto final.A menudo se registran de manera jerárquica.El producto terminado aparece en la parte superior y en los materiales inferiores y los componentes individuales.Actúa como una fuente clave de los materiales que se utilizan en la fabricación del producto final.En el módulo de fabricación Odoo 15, puede configurar la factura de materiales y vincular múltiples facturas de materiales a un solo producto.Las características que se pueden habilitar con la factura de materiales de Odoo son:

Optional Routing: You can generate new routing for the existing work orders or new on new orders.

Version Changes: With BoM you can include configurable alternatives while new orders are created.

Phantom Bill of Materials: The case when products are sold as semi finished products in kits, or the sale of replacement parts you can easily execute such cases with BoM.

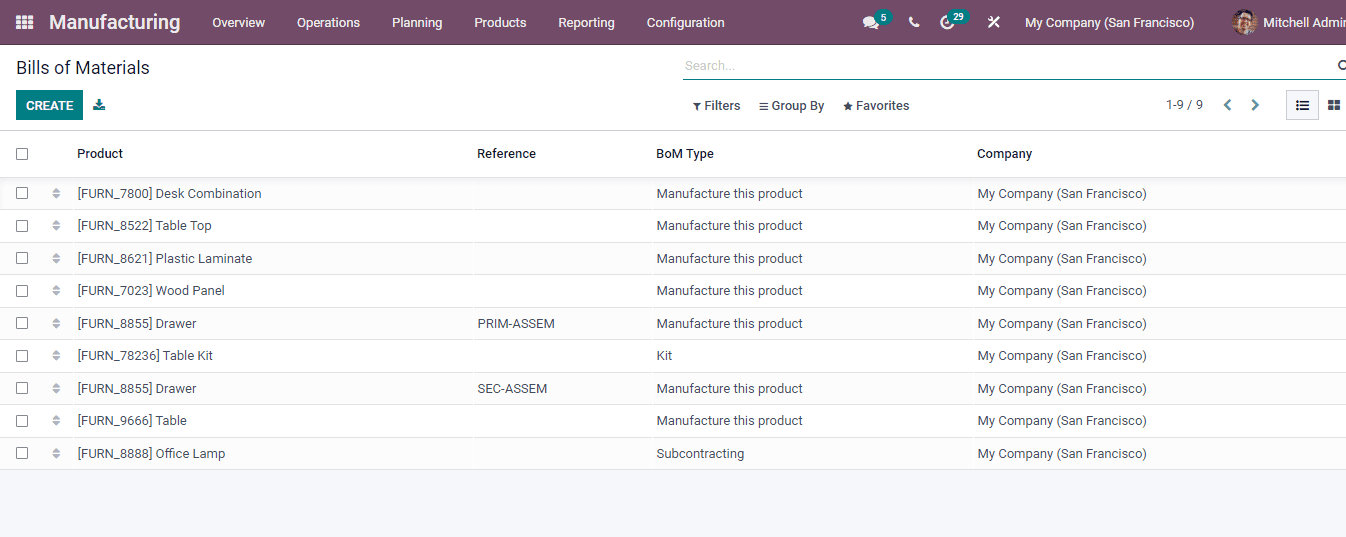

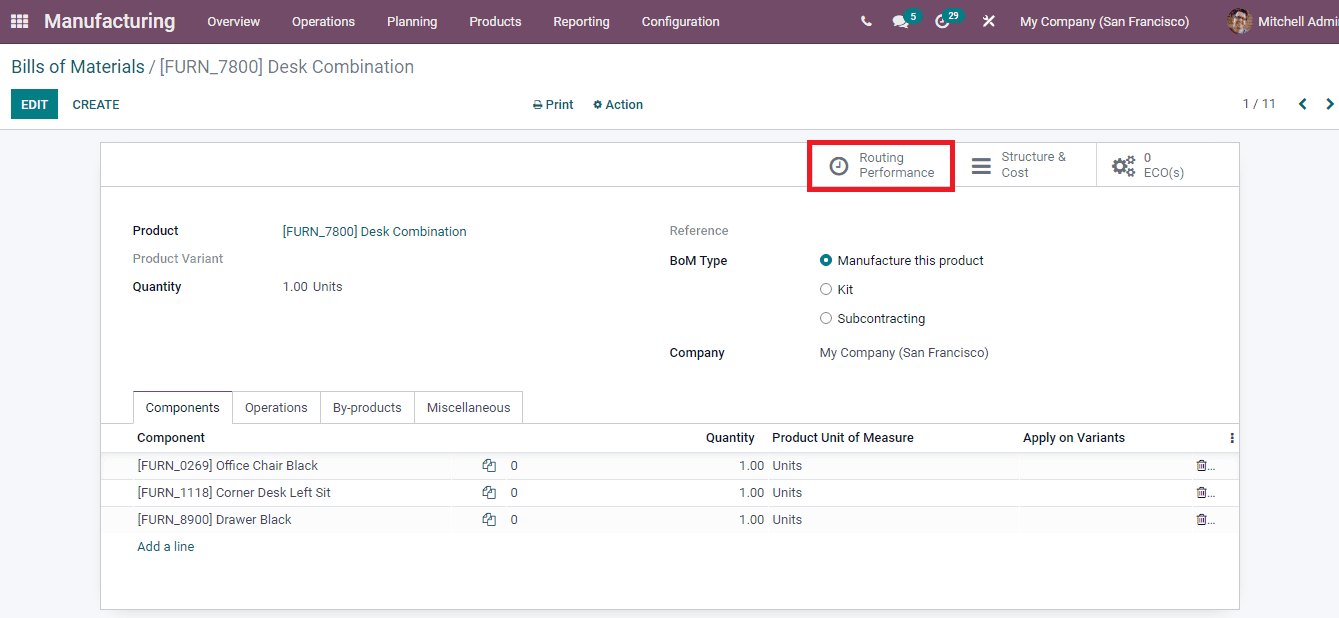

You can view the bill of order in the Odoo Manufacturing module by selecting the Bills of Materials option from the Products tab. It is not necessary to create or assign the routing of the BoM in some cases. The manufacturing will be completed in a single step and routing is not necessary in such cases.

By selecting the Bill of Materials you can view the list of Products along with their details such as the Reference, BoM Type and name of the Company. You can Filter the products and display them on their types such as the Manufacturing and Kit. The result can also be grouped on the basis of Product, BoM Type and Unit of Measure. The bill of materials can be viewed in List and Kanban view.

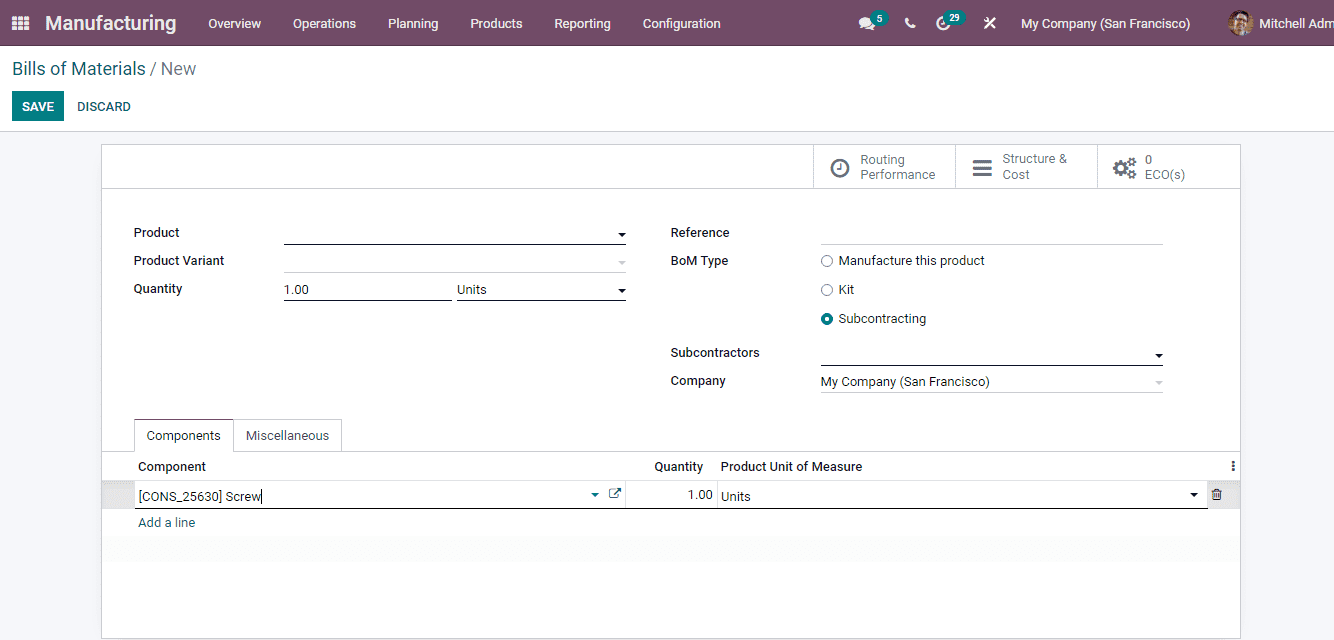

You can generate new bills of materials by selecting the CREATE button. At the new bills of material form page add the details such as

Product: At the product field you can add the name of the product from the drop down menu or else can create a new product in the database.

Product Variant: By adding a product variant to this field you can define the bills of materials to the specific variant.

Quantity: The quantity of the product that has to be manufactured along with the unit of measure must be inserted in this field.

Reference: By adding a reference you can distinguish the creating bill of materials from others.

BoM Type: Odoo allows you to select one from the three types of the bills of material type. These are Manufacture this Product, Kit and Subcontracting. Manufacturing this Product type will categorize that the product will be fully manufactured and given to the customer. Kit type of BoM can be selected if the product is splitted into categories. This can be selected at the creation of a manufacturing order and also at the time of creation of a stock transfer. Subcontracting types can be selected when the unfinished products are given to the subcontractors. While selecting the subcontracting type you will also have to specify the name of the Subcontractor.

Company: Insert the name of the company in this field.

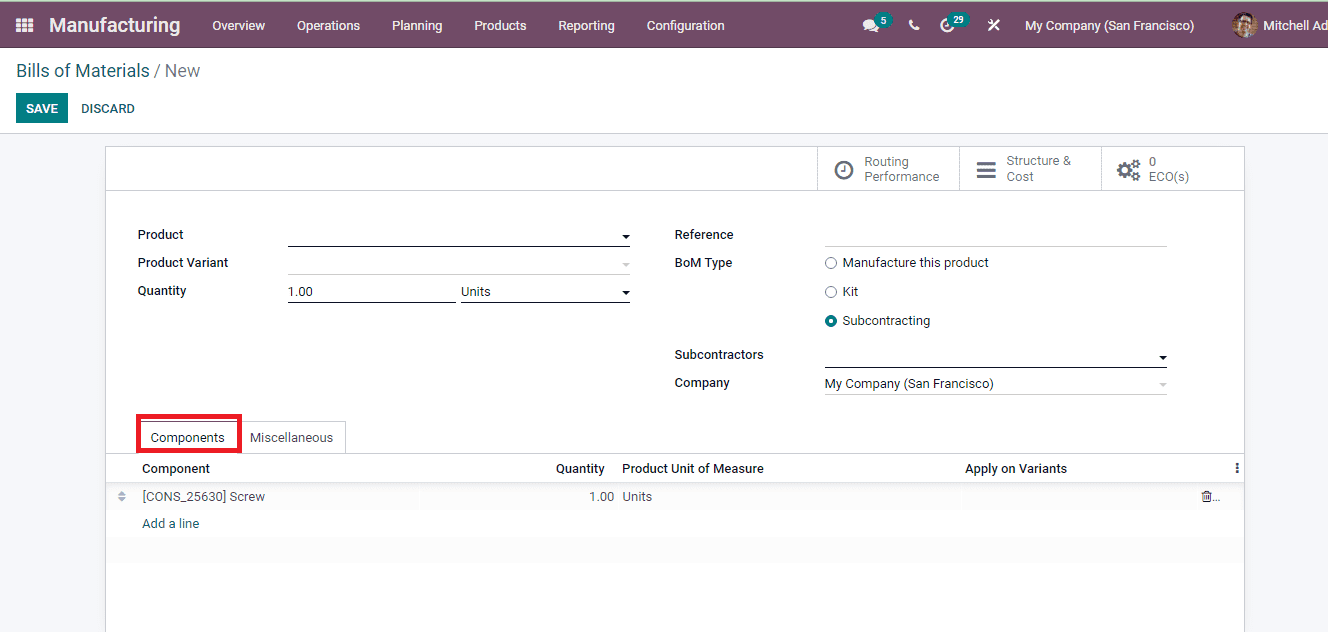

Apart from this there are two tabs which have to be filled. They are Components and Miscellaneous. In the Components you can include the components used by selecting the Add a Line option. After selecting the components you can configure their Quantity and Product units of Measure. Multiple components can be added using the Add a Line option. You can also apply the BoM on the variants of the products.

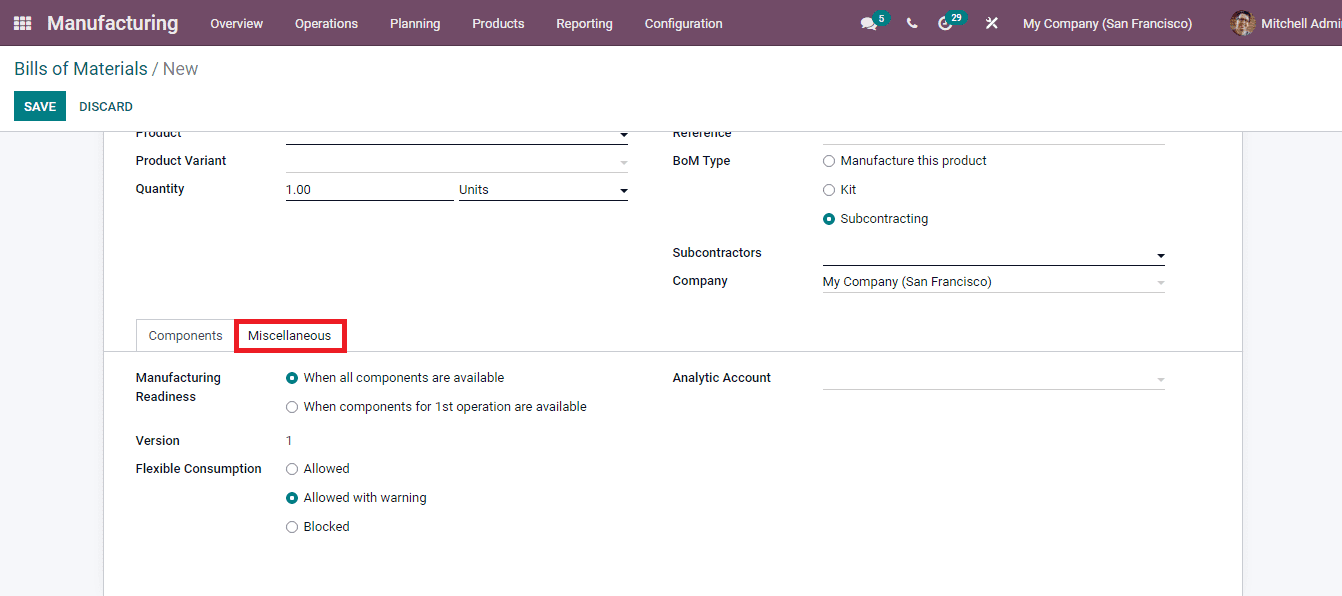

At the Miscellaneous tab you can define when the manufacturing order is considered as ready to get started at Manufacturing Readiness. This can be when all components are available or when components for the 1st operation are available. At Flexible Consumption you can define if you can consume more or less components than the quantity defined on the Bills of Materials. You can enable either Allowed, Allowed with warning or Blocked. By enabling Allowed the consumption above the defined quantity is allowed for all the manufacturing users. Allow with warning allows the manufacturing users to consume more with a summary of consumption differences when closing the manufacturing order. By selecting the Blocked option, only a manager can close the manufacturing order when the bills of material consumption are not followed. The Analytic Account in which the cost and revenue entries will take place for financial management of the manufacturing order. The values set here are company specific values.

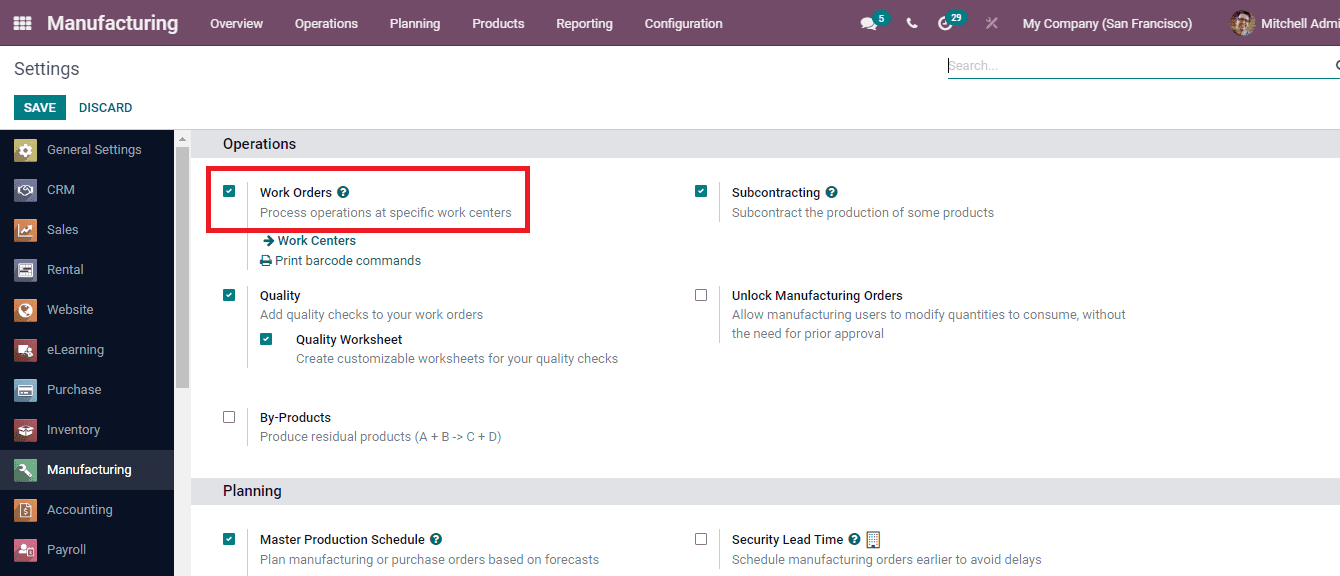

You can add routing to the BoM. In order to set up the routing, you will have to enable the Operations tab in the BoM. For that select the Settings option from the Configuration tab. From the Settings, enable the Work Orders option. This will help you to display the Operations tab in the new Bills of Materials page.

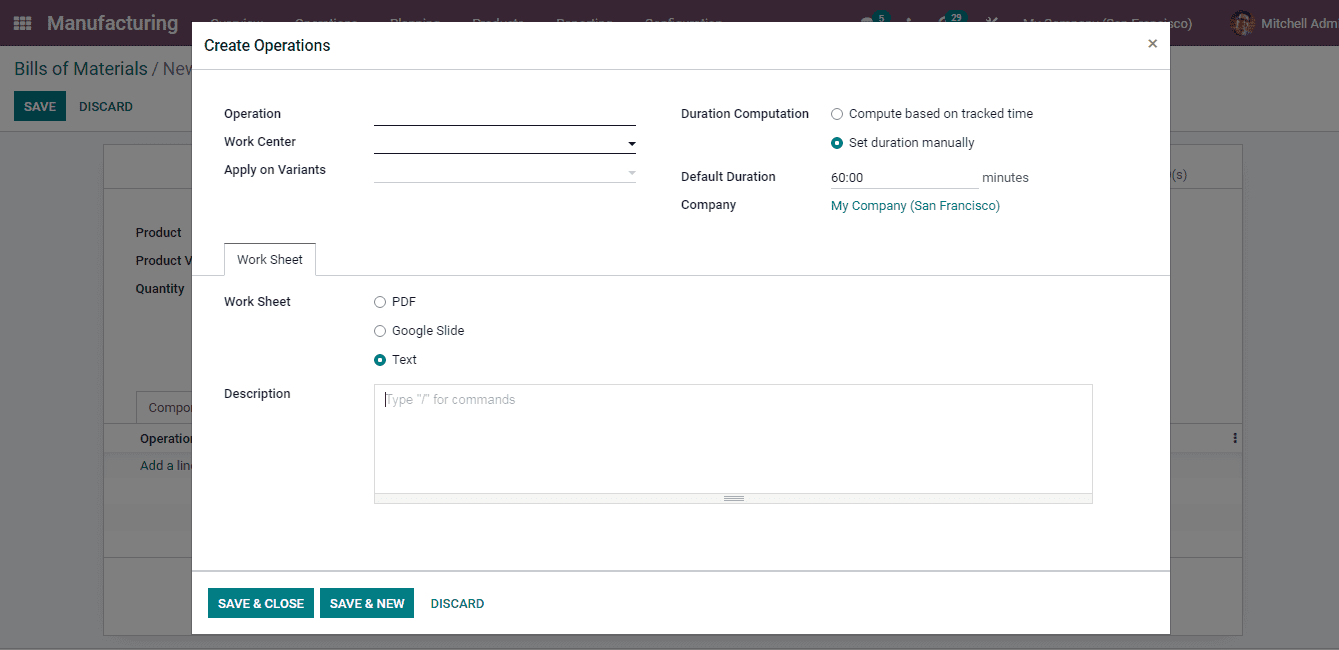

At the Operations tab, you can either copy the existing operations or create new ones. To create a new one, select the Add a Line option. At the Create Operations window enter the details such as:

Operations: Define the activity that will be executed in this field.

Work Center: Select the work center from the drop down menu where the manufacturing process will be done.

Apply on Variants: Add the variant for which the mentioned Bill of Materials will be applied.

Duration Computation: You can define the way in which the time required for the process should be calculated. It can be either Compute based on tracked time or Set duration manually. When the Compute based tracked time is enabled, you must enter Based on how many work orders and the Default Duration of the process. When the Set duration manually is enabled, you need to enter the Default Duration time in minutes.

Company: Enter the name of the company in this given field.You can also see the Work Sheet tab where you can select the mode of Work Sheet as either PDF, Google Slide or Text. You will receive the detailed instruction of the work as per the chosen option. A detailed Description of the work can be added at the box provided.

By selecting the Save & Close button you can add the details to the Bills of Materials or else you can select the Save & New button to save the created operation and add another new operation.

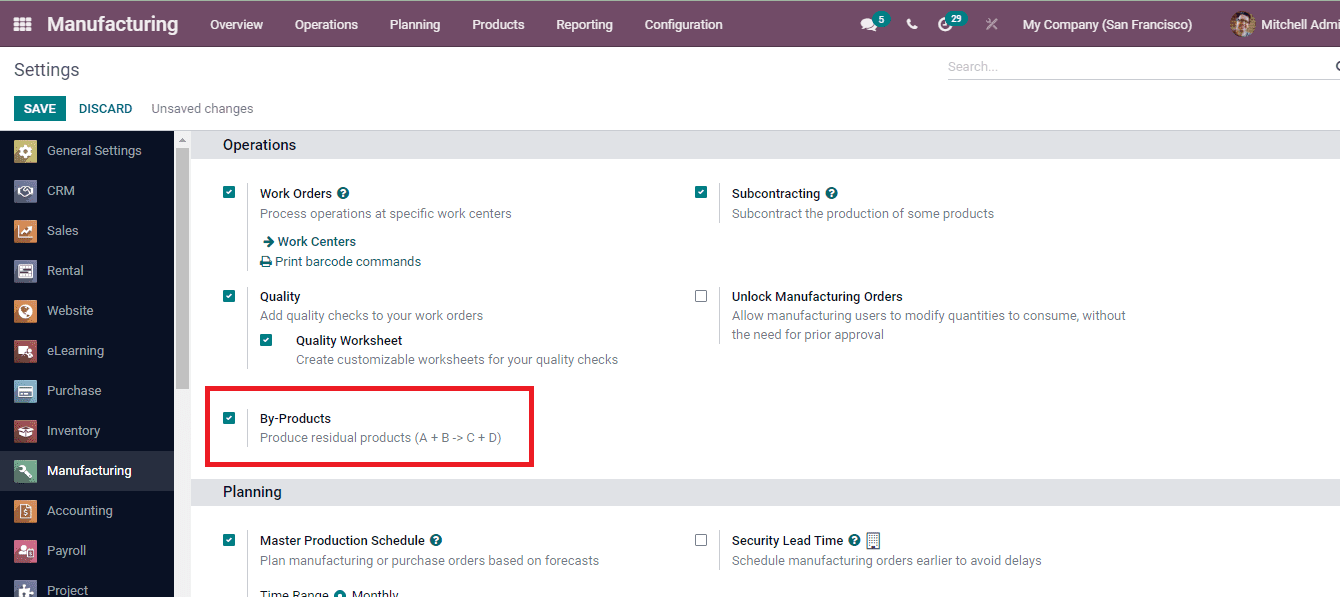

Adding by-products to the Bills of Materials is very simple in Odoo. By- products are those products that are manufactured along with the main products in Bills of Materials. To enable adding by- products to the bills of materials, select the Settings option from the Configuration tab. In the Settings, enable the By - Products option. By enabling this you can also get several finished products.

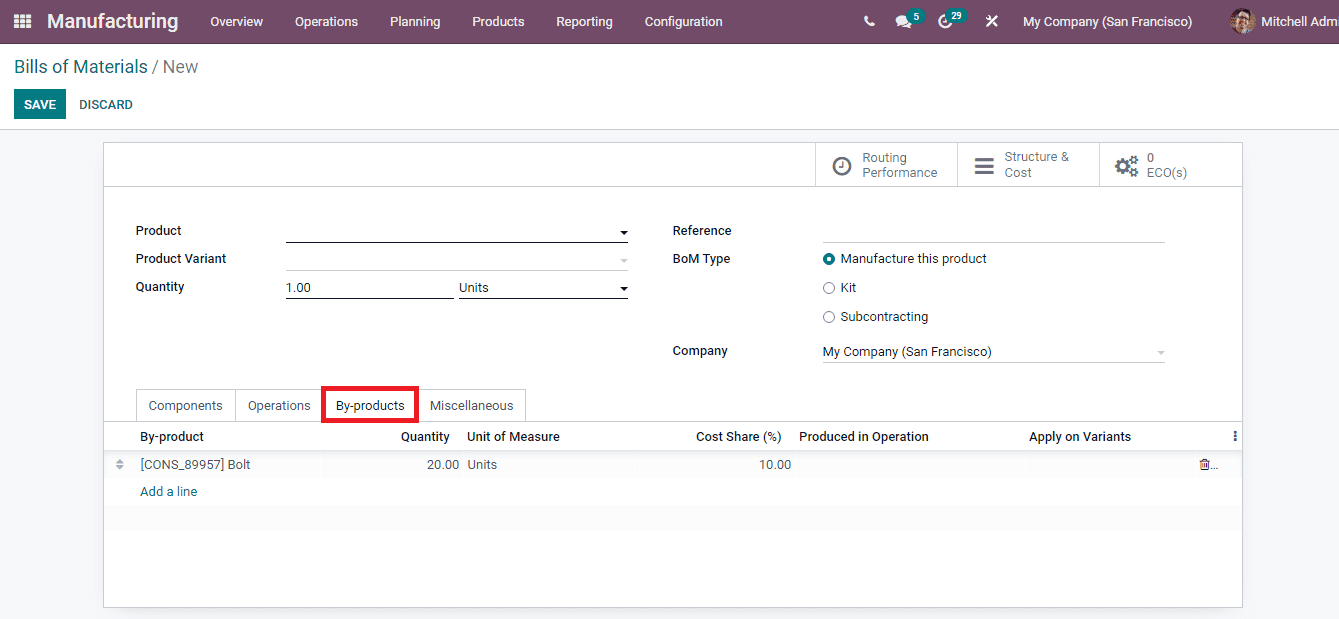

By selecting the new bills of materials, you can view the newly created By- Products tab. At the tab, add the details such as the name of the by product using the Add a Line option. You can configure the Quantity, Unit of Measure, Cost Share percentage and add the Produced in Operation and the variants of the products on which the same should be applied. Multiple by- products can be added by selecting the Add a Line option.

The data of the routing can be viewed by selecting the Routing Performance tab situated at the top. This will give you the statistics of the work orders' duration related to the selected productâs routing.

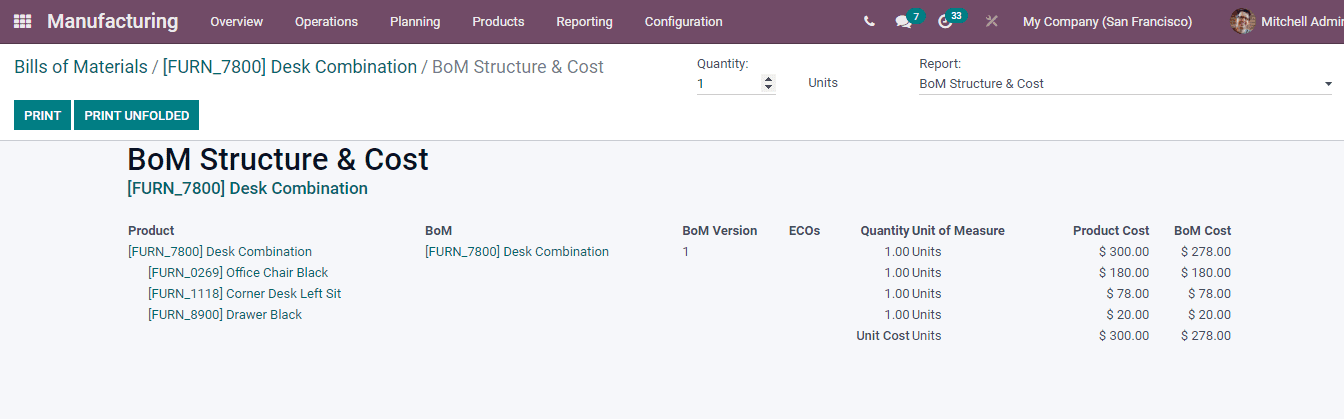

The bill of materials structure and cost related data will provide you the insight of the product cost as well as the BoM cost. To view them select the Structure and Cost tab. The report of the products used along with other details such as the version of bills of materials, quantity used for the production and the costs of them. You can compare the production cost and the bills of materials cost from the displayed report. You can either view the Structure and Costs report in a single document or display the Structure report alone. The unfolded and folded reports can be saved using the PRINT and PRINT UNFOLDED buttons respectively. The report can also be configured according to the quantity.

Odoo allows you to keep a track of the ECO (Engineering Change Orders) from the Manufacturing module. Changes can be made after submitting the related documents and receiving an approval from the authority. The ECOs related to the bills of materials can be viewed by selecting the ECO tab.