-

- Acuerdos de compra

- Advertencia

- Atributos del producto

- Categoria de ProductO

- Coincidencia de Recibos de Compra y Facturas de 3 Vías

- Compra

- Gestión de Productos

- Gotero

- Ordenes de Compra

- Receptores productos

- Reportes

- RequestForQuotationPurchaserOrder

- Unidad de Medida

- UnitfMeAsurectatecturaciones

- Vendorbills

- Vendormanagació

-

- Administrador

- Billofmateriales

- CREACIÓN DE DOCUMENTOS

- Categoría de equipos

- Configuraciones de WorkCenters

- CorrectiveMaintenancerequest

- Creando Merman Oferta

- Creando una orden de reparacia

- Enrutamiento

- Fabricación

- Gerencia

- Gerencia de Reparacia

- Gestión de la Calidad

- Gestión del Ciclo de Vida del Producto

- HowtounBuildOrder

- Manejo de Mantenimiento

- ManufacturingOrderManagement

- Mermanes de Creendo

- Nobildaproducto

- Orden

- Planificación de Trabajadores

- Planificante

- Preventivemaintenancerequest

- Productora de administración

- QualityControlpoints

- Reportes

- Subcontratacia

- WorkCenters y Rutings

- Workcenters

-

- Ajustes de Inventario

- Anuncios

- Capacidad de Productos

- Categorizacia de productos

- Configuración del producto

- Confirmación de Correo Electrónico de Entrega

- Consiguio un

- Coste de Aterrizaje

- Entrega

- Gestión de Almacenes

- Horario de Programació

- IntegratingthirdPartyshipper

- Inventario

- Operaciones de inventario

- Paquetes de Entrega

- Parpadeo

- Planificador

- ProductVariants

- Ratidrategas

- Reglas y rutas

- Reportes

- SMSCONFirmationAtDelivery

- Ubicacia

- Unidades de Medida

Odoo 14 book

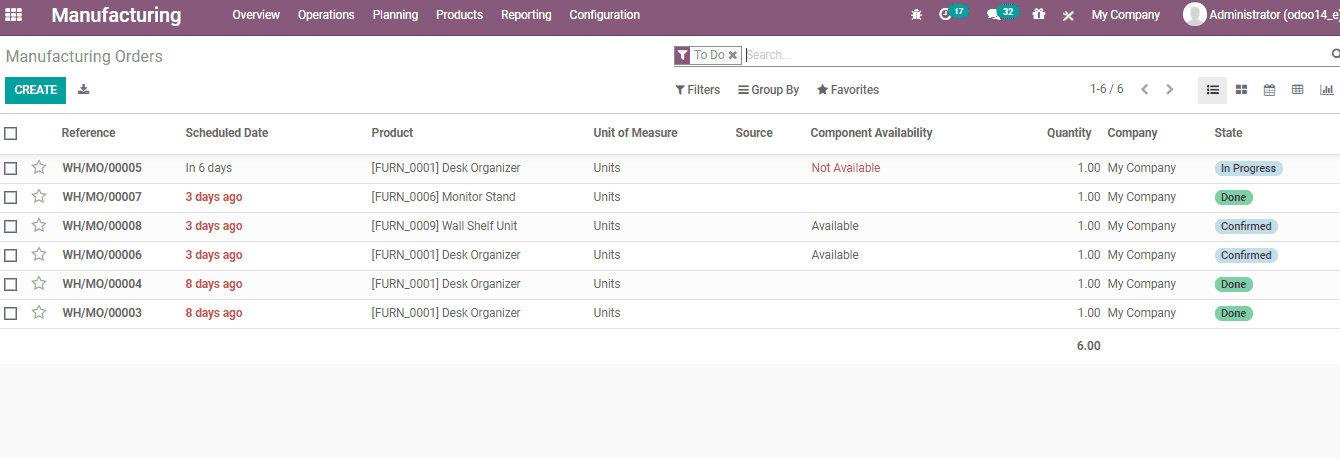

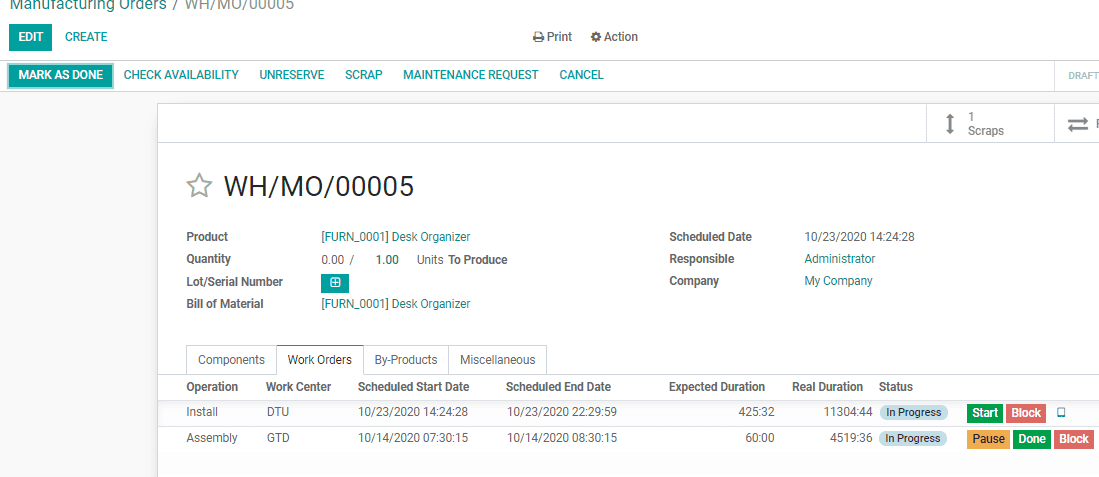

Manage production

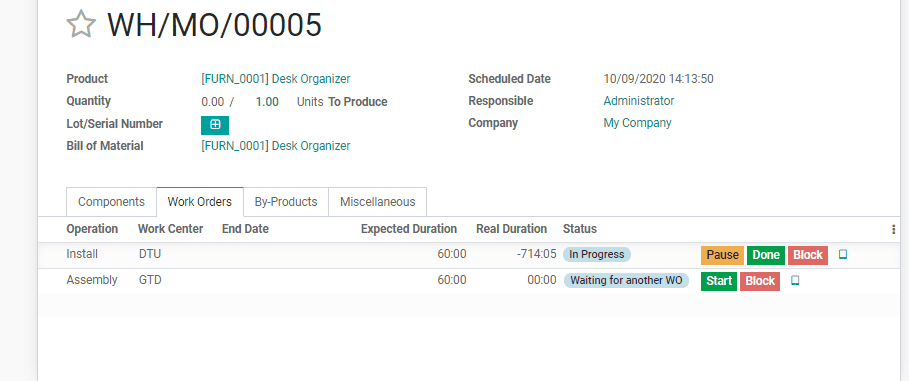

After creating and confirming the MO the user can start the production of the goods. Odoo enables you to get a glance of all Manufacturing orders. For this, Go to Manufacturing > Operations > Manufacturing Orders> Work Orders. You can view the status of all on-going manufacturing orders from this place.

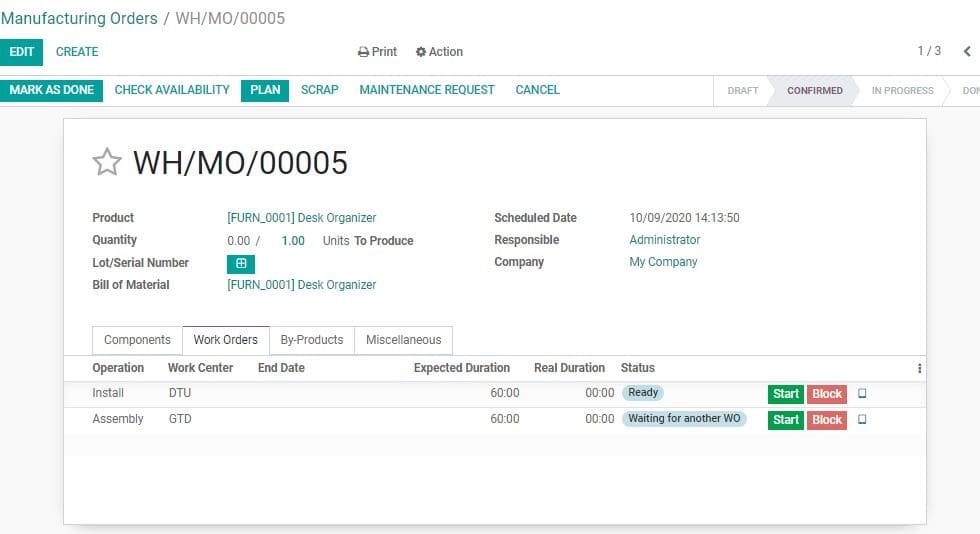

Now, you can select a Manufacturing Order from the list.

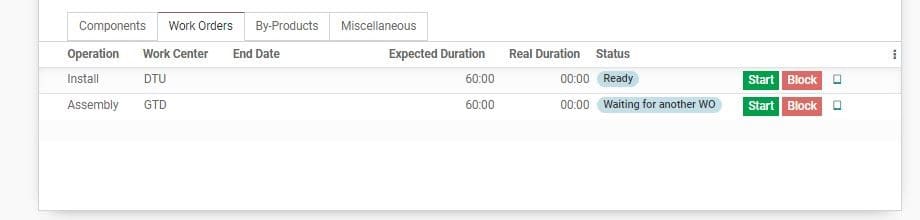

Now go to work orders tab

On clicking Start the status will change as given below

Here, you can Pause the production, mark the production as done or Block the production.

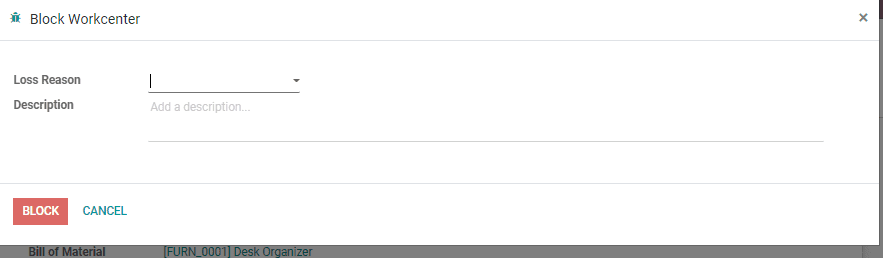

On clicking the BLOCK button, the user will be directed to a new wizard. The user can enter the reason for blocking at LOSS Reason.

The user can also add additional description if wanted and then go ahead with Blocking.

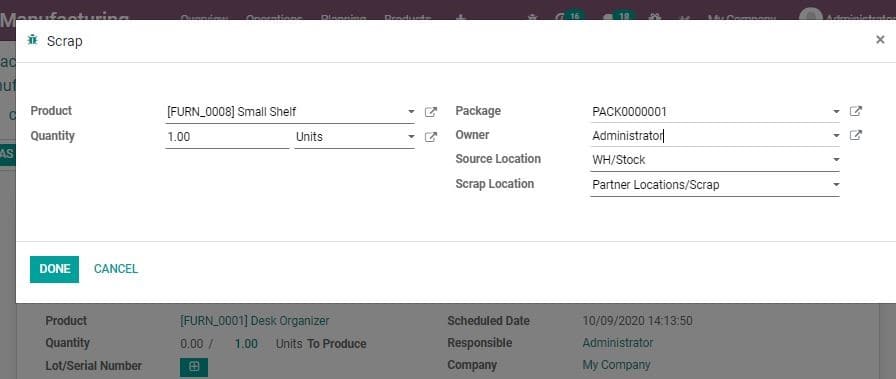

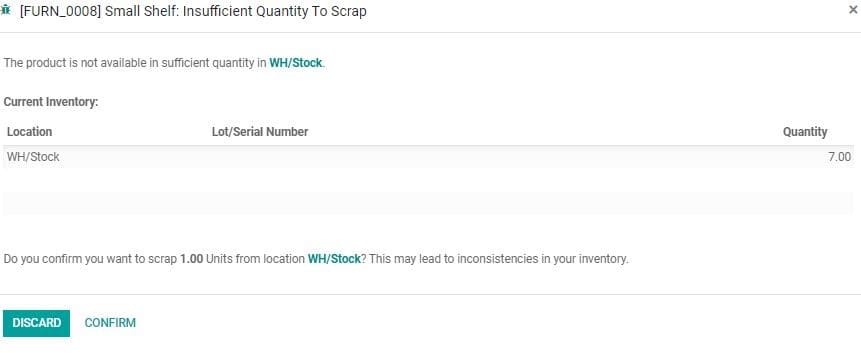

If you want to mark the products as SCRAP, you can click on scrap button

You will get a new window here.

Here the user can enter product, quantity, package, owner source location and scrap location.

On clicking scrap button, a new window will be opened

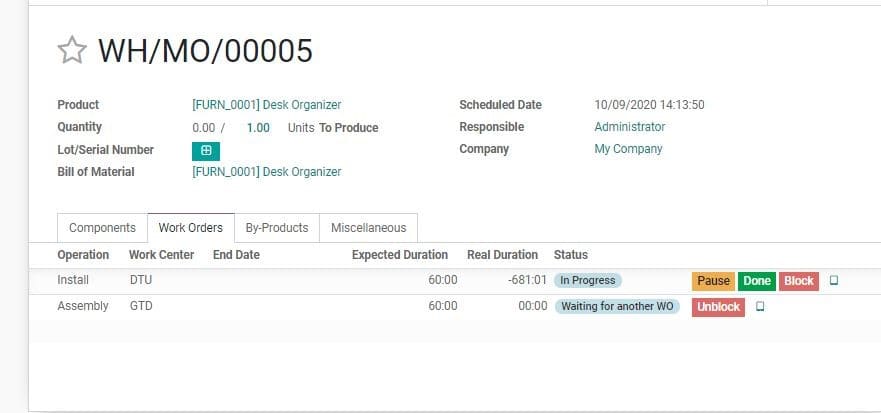

Now, go back to MO

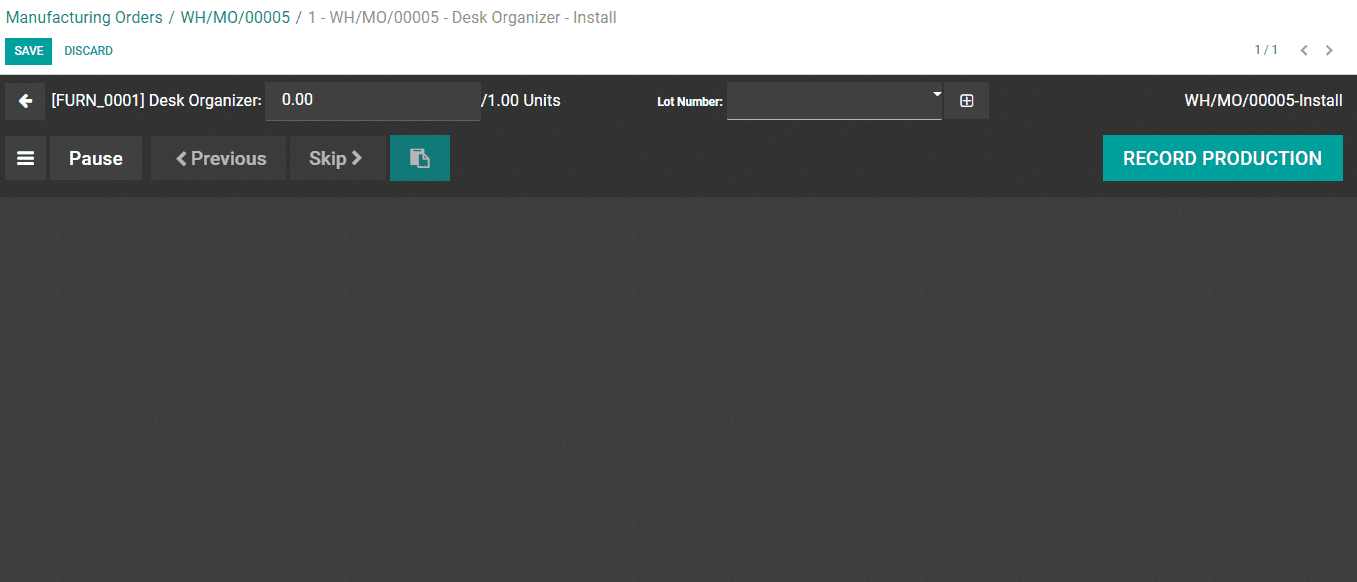

On the right hand side of the work order, next to the red button, you can find an external link. On clicking this, you will be taken to a new window where you can access instructions for manufacturing, if any.

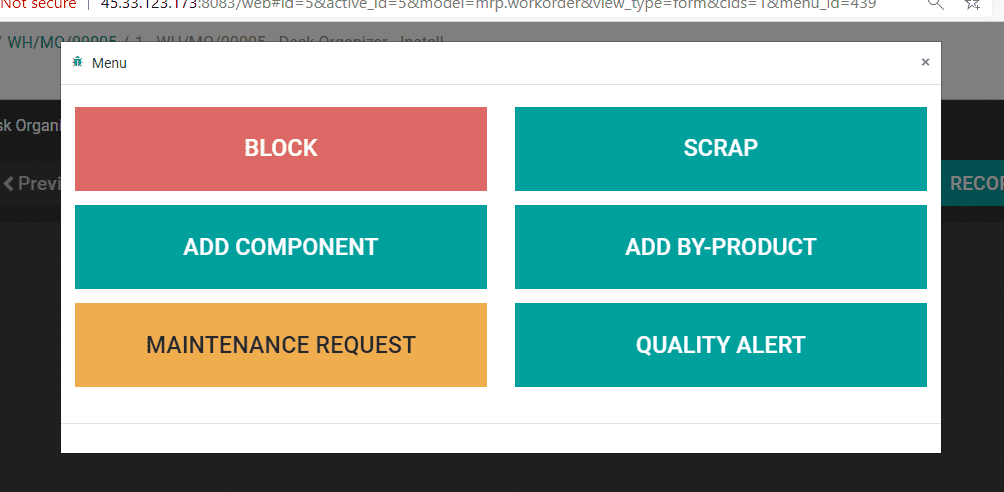

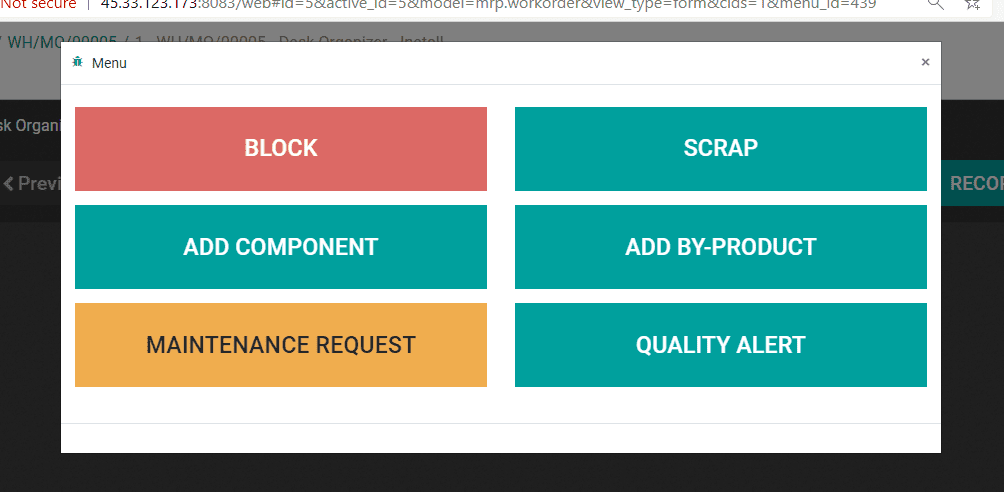

Here, you can record the production and get instructions. You can carry out scrap, block and other activities here also.

You can click on the menu tab to get the below given options

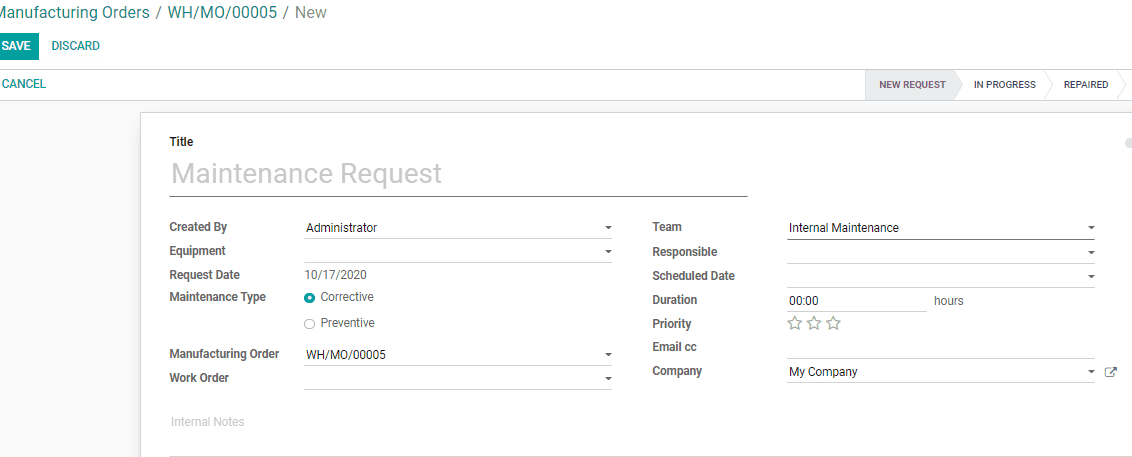

Maintenance Request button

Upon clicking MAINTENANCE REQUEST button is available in the both windows as given below

On clicking on the button a new window requesting the type of maintenance will be opened: Preventive or Corrective maintenance. Here, one can specify several other details like manufacturer, equipment, manufacturing order and so forth.