-

- Acuerdos de compra

- Advertencia

- Atributos del producto

- Categoria de ProductO

- Coincidencia de Recibos de Compra y Facturas de 3 Vías

- Compra

- Gestión de Productos

- Gotero

- Ordenes de Compra

- Receptores productos

- Reportes

- RequestForQuotationPurchaserOrder

- Unidad de Medida

- UnitfMeAsurectatecturaciones

- Vendorbills

- Vendormanagació

-

- Administrador

- Billofmateriales

- CREACIÓN DE DOCUMENTOS

- Categoría de equipos

- Configuraciones de WorkCenters

- CorrectiveMaintenancerequest

- Creando Merman Oferta

- Creando una orden de reparacia

- Enrutamiento

- Fabricación

- Gerencia

- Gerencia de Reparacia

- Gestión de la Calidad

- Gestión del Ciclo de Vida del Producto

- HowtounBuildOrder

- Manejo de Mantenimiento

- ManufacturingOrderManagement

- Mermanes de Creendo

- Nobildaproducto

- Orden

- Planificación de Trabajadores

- Planificante

- Preventivemaintenancerequest

- Productora de administración

- QualityControlpoints

- Reportes

- Subcontratacia

- WorkCenters y Rutings

- Workcenters

-

- Ajustes de Inventario

- Anuncios

- Capacidad de Productos

- Categorizacia de productos

- Configuración del producto

- Confirmación de Correo Electrónico de Entrega

- Consiguio un

- Coste de Aterrizaje

- Entrega

- Gestión de Almacenes

- Horario de Programació

- IntegratingthirdPartyshipper

- Inventario

- Operaciones de inventario

- Paquetes de Entrega

- Parpadeo

- Planificador

- ProductVariants

- Ratidrategas

- Reglas y rutas

- Reportes

- SMSCONFirmationAtDelivery

- Ubicacia

- Unidades de Medida

Odoo 14 book

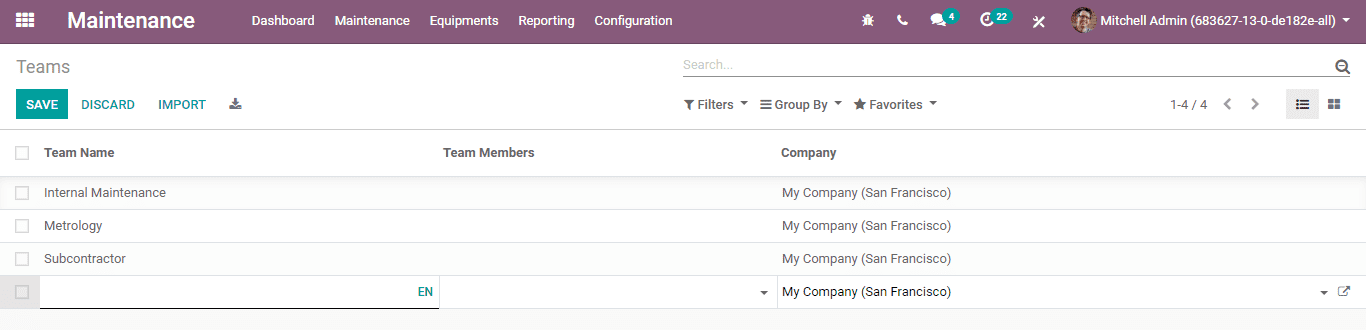

Creating maintenance team

Configuration:

Maintenance > Configuration > Maintenance Teams> Create.

Here, the user can add the name of the team, team members and can also choose a company for creating maintenance team.

Now let us go back to creating an equipment,

Technician: Technician who takes care of the equipment.

Assigned Date: Add assigned date if any. For example, if the equipment is used by an employee, the user can specify the date on which the equipment was assigned to that employee.

Scrap date: Add scrap date based on its durability.

Used in location: Location where equipment is used.

Work Center: Work center of the equipment if any.

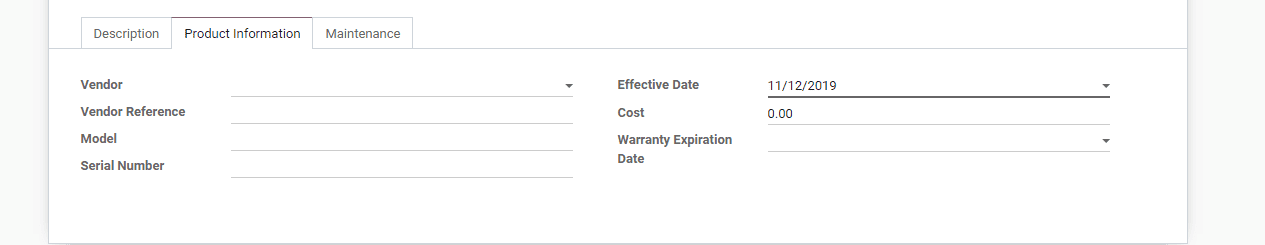

Product information tab

The user can add details pertaining to the equipment. For example, when it was bought.

Add details of vendor associated to the equipment, vendor reference, the equipment model, serial number, Effective date (the date at which the equipment became effective. The date given here will be used to compute the Mean Time Between Failure, equipment cost and warranty expiration date.

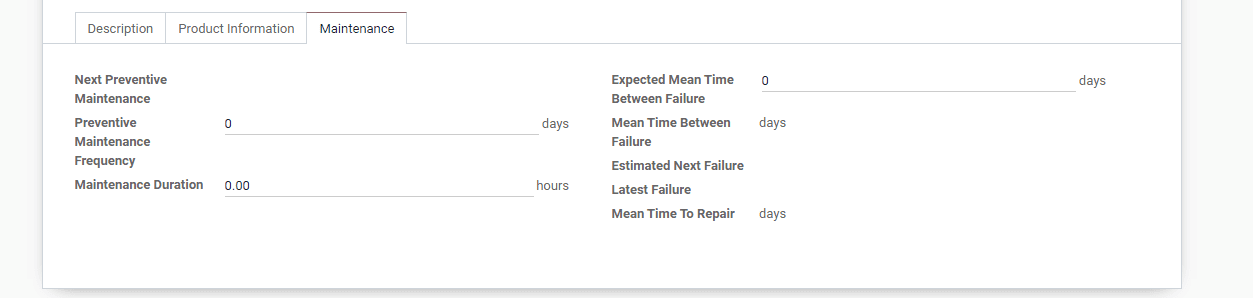

Under Maintenance tab

Here you can find details pertaining to the maintenance

Preventive Maintenance Frequency: Set the frequency of preventive maintenance in number of days.

Next Preventive Maintenance: After setting preventive maintenance the next preventive maintenance date will get automatically set based on that. This will be calculated based on the effective date.

Maintenance duration: Duration of maintenance

Expected Mean Time Between Failures: The user can set the expected mean time between failures in days.

Mean Time Between Failures(MTBF): This period can be calculated based already performed corrective maintenances.

Estimated Next Failure: Latest Failure Date+ MTBF.

Latest failure: This field will be updated automatically.

Mean Time To Repair (MTTR): Average time between maintenance and repair in days. If the maintenance started on 4nd April and equipment got repaired on 5 April we can calculate the repair mean time to repair as 1 day.