-

- Acuerdos de compra

- Advertencia

- Atributos del producto

- Categoria de ProductO

- Coincidencia de Recibos de Compra y Facturas de 3 Vías

- Compra

- Gestión de Productos

- Gotero

- Ordenes de Compra

- Receptores productos

- Reportes

- RequestForQuotationPurchaserOrder

- Unidad de Medida

- UnitfMeAsurectatecturaciones

- Vendorbills

- Vendormanagació

-

- Administrador

- Billofmateriales

- CREACIÓN DE DOCUMENTOS

- Categoría de equipos

- Configuraciones de WorkCenters

- CorrectiveMaintenancerequest

- Creando Merman Oferta

- Creando una orden de reparacia

- Enrutamiento

- Fabricación

- Gerencia

- Gerencia de Reparacia

- Gestión de la Calidad

- Gestión del Ciclo de Vida del Producto

- HowtounBuildOrder

- Manejo de Mantenimiento

- ManufacturingOrderManagement

- Mermanes de Creendo

- Nobildaproducto

- Orden

- Planificación de Trabajadores

- Planificante

- Preventivemaintenancerequest

- Productora de administración

- QualityControlpoints

- Reportes

- Subcontratacia

- WorkCenters y Rutings

- Workcenters

-

- Ajustes de Inventario

- Anuncios

- Capacidad de Productos

- Categorizacia de productos

- Configuración del producto

- Confirmación de Correo Electrónico de Entrega

- Consiguio un

- Coste de Aterrizaje

- Entrega

- Gestión de Almacenes

- Horario de Programació

- IntegratingthirdPartyshipper

- Inventario

- Operaciones de inventario

- Paquetes de Entrega

- Parpadeo

- Planificador

- ProductVariants

- Ratidrategas

- Reglas y rutas

- Reportes

- SMSCONFirmationAtDelivery

- Ubicacia

- Unidades de Medida

Odoo 14 book

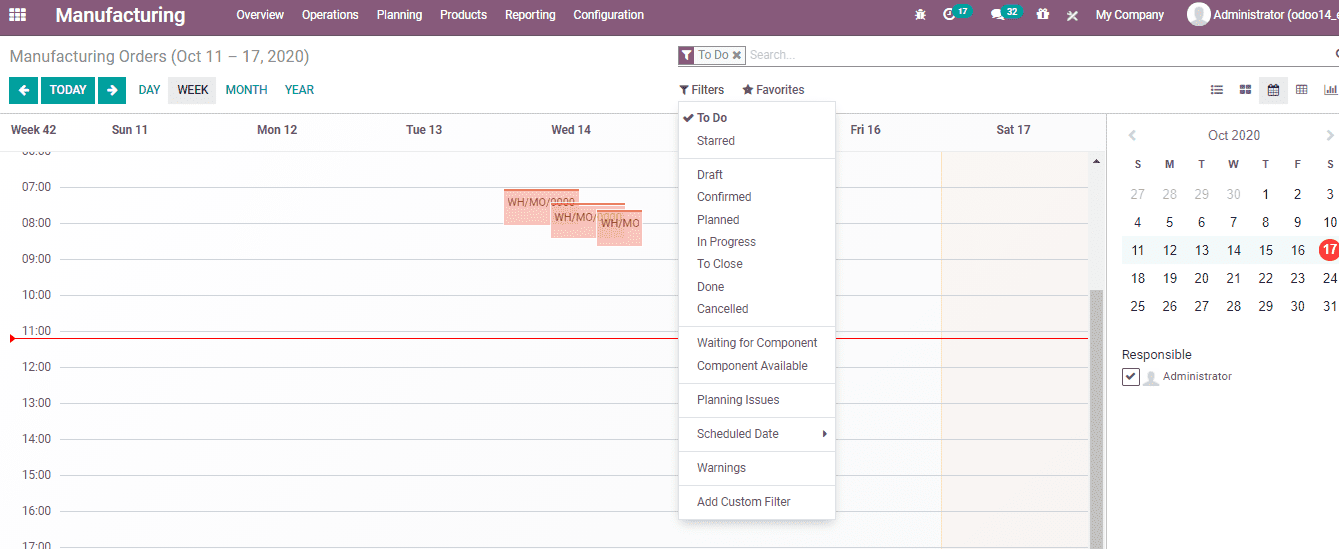

Planning work orders

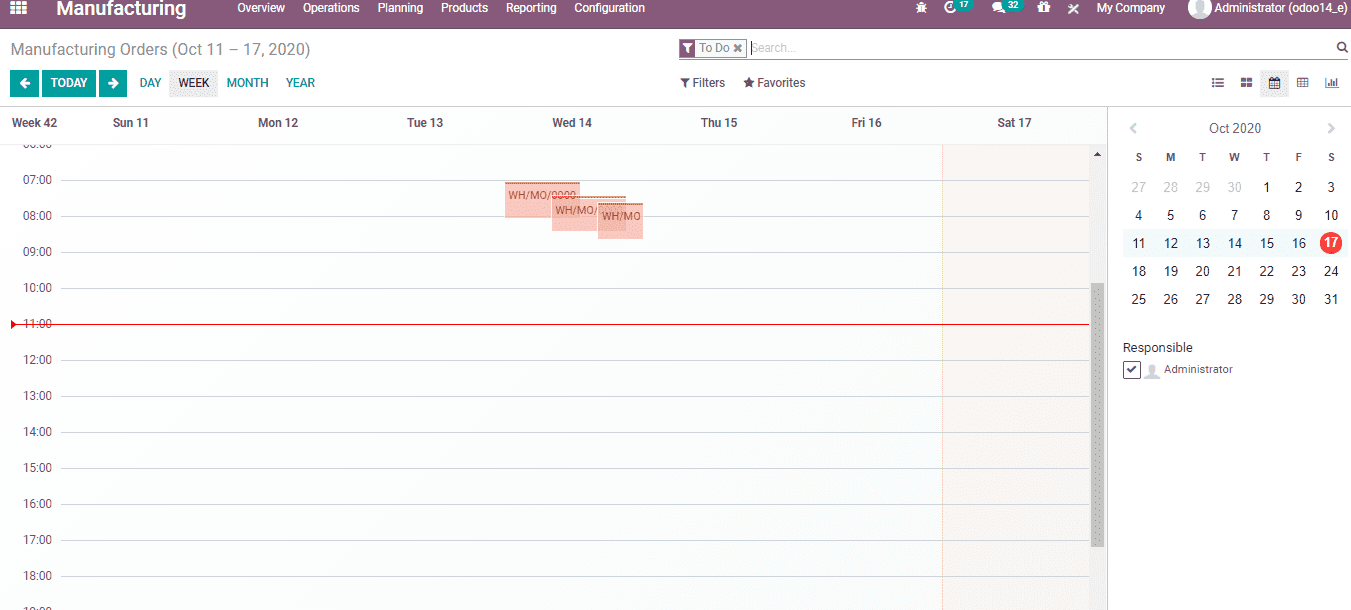

Sometimes, the manufacturing industry will have to plan their work orders. This will help the investors to arrange the work for the entire day. This ensures the smooth completion of all works. This also prevents the user from wasting time on planning numerous work orders simultaneously.

Odoo 14 helps the user to schedule the beginning date for their manufacturing order. Besides, in situations when you plan two work orders at a similar work centre, at that hour, Odoo will help you to schedule the subsequent work just after completing the first.

Configuration:

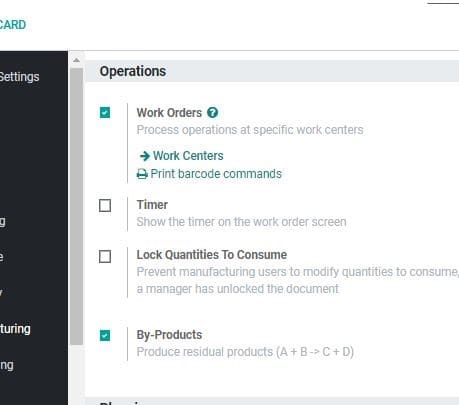

Manufacturing ->Configuration -> Settings and activate Work Orders feature under Operations Menu.

Click SAVE and mark the changes.

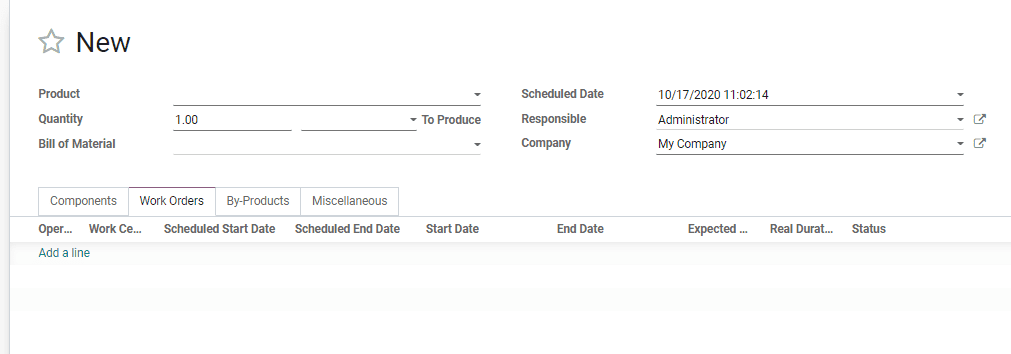

In the next step, go to Manufacturing> Operations> Manufacturing Orders. Create new order with planned start date.

Create Manufacturing Order as to do and plan it by clicking Planning menu. Her, the user can access the scheduled orders.

Master Production Schedule (MPS)

It is an important tool provided by Odoo to forecast your demand.

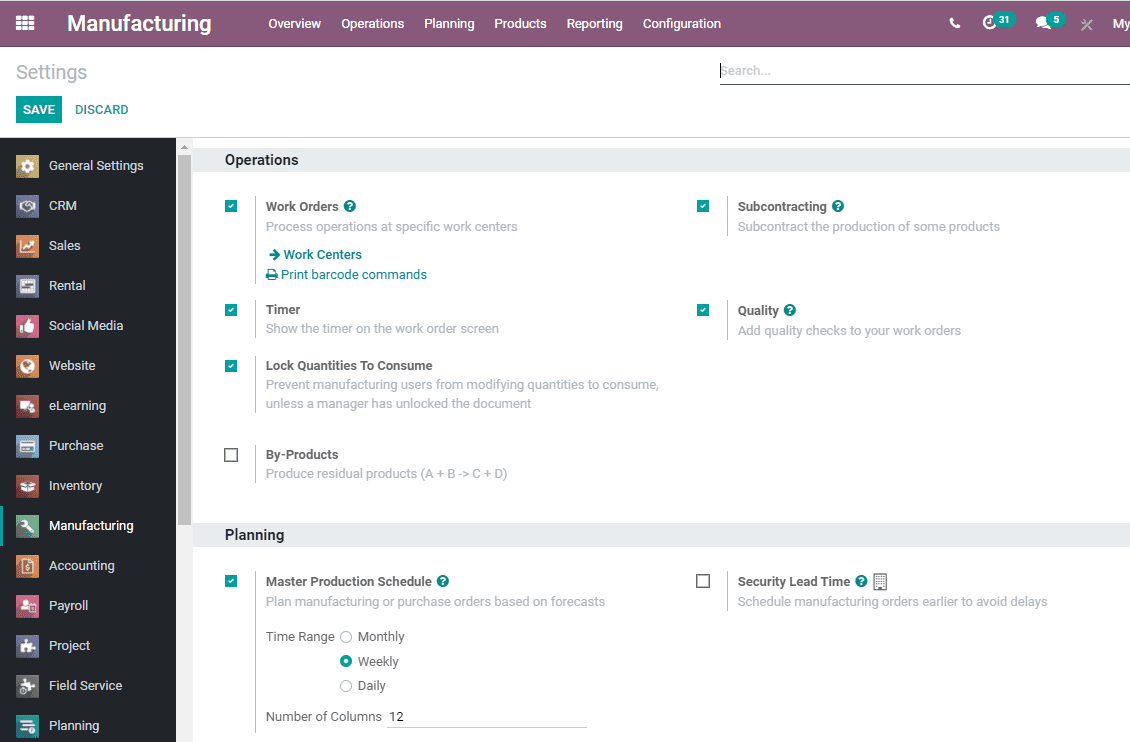

Configuration

To configure MPS, you have to go to the Manufacturing app ⣠Configuration ⣠Settings> Planning

Here, you have to enable the Master Production Schedule feature. Then click Save button.

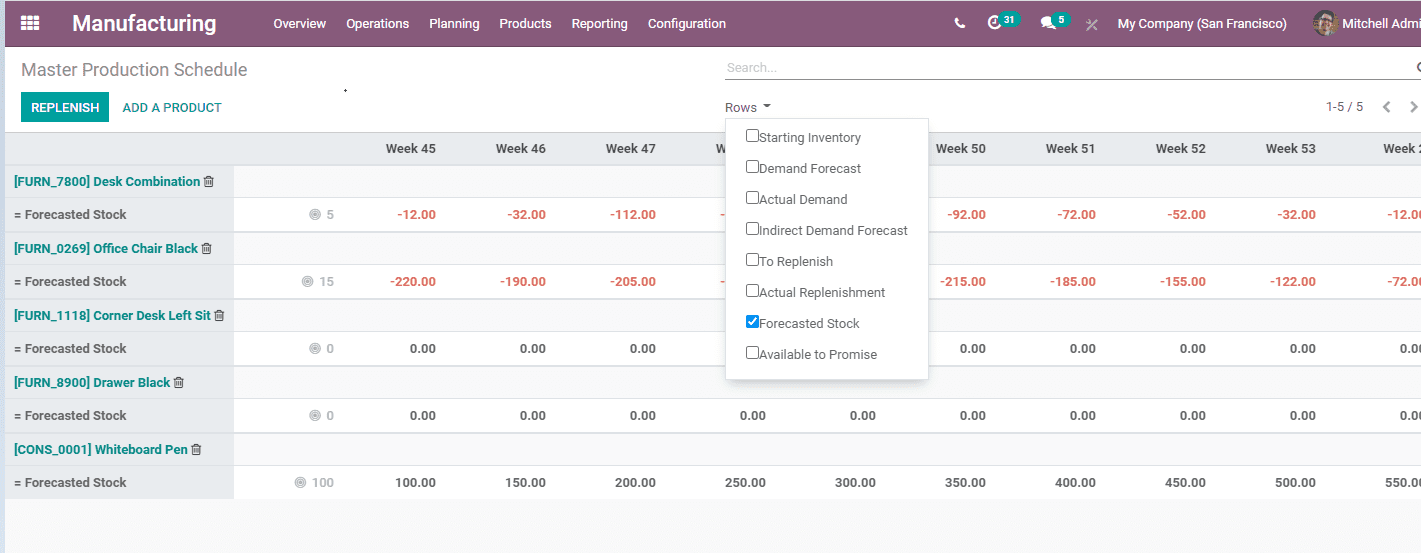

After Saving the changes, go to Planning ⣠Master Production Schedule.

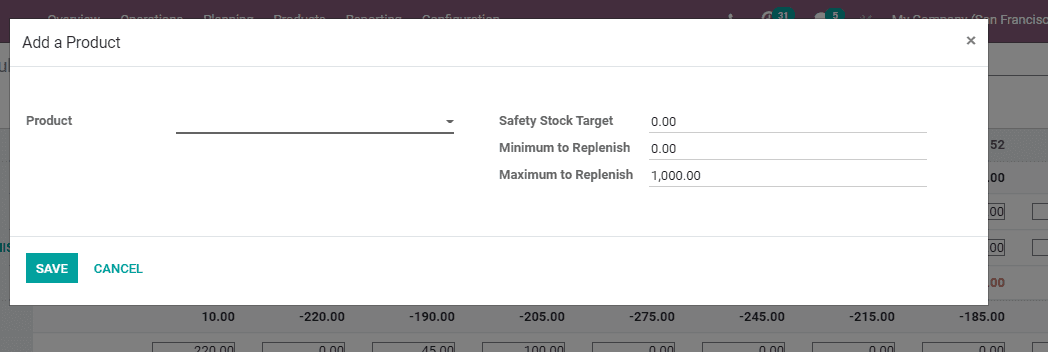

Here, you have two options- Replenish or Add a product.

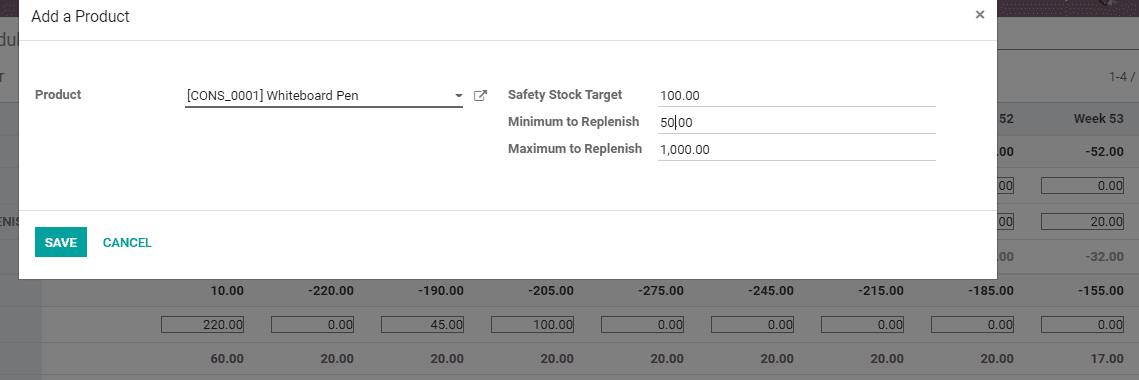

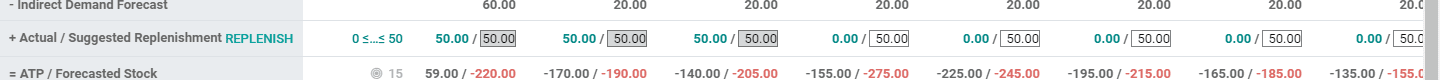

Let us click Add a Product button. You will get a new window as given below. Here you can define the safety stock target of the product. Safety stock target is the stock that you want to have on hand at the end of a particular period. The user can also add the minimum and maximum quantities to replenish.

Now, click Save button.

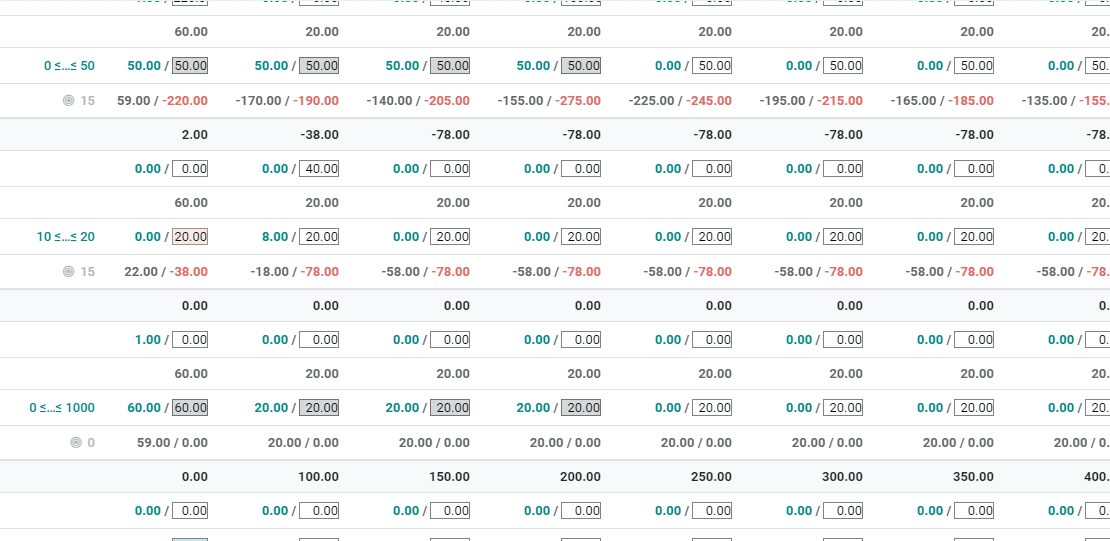

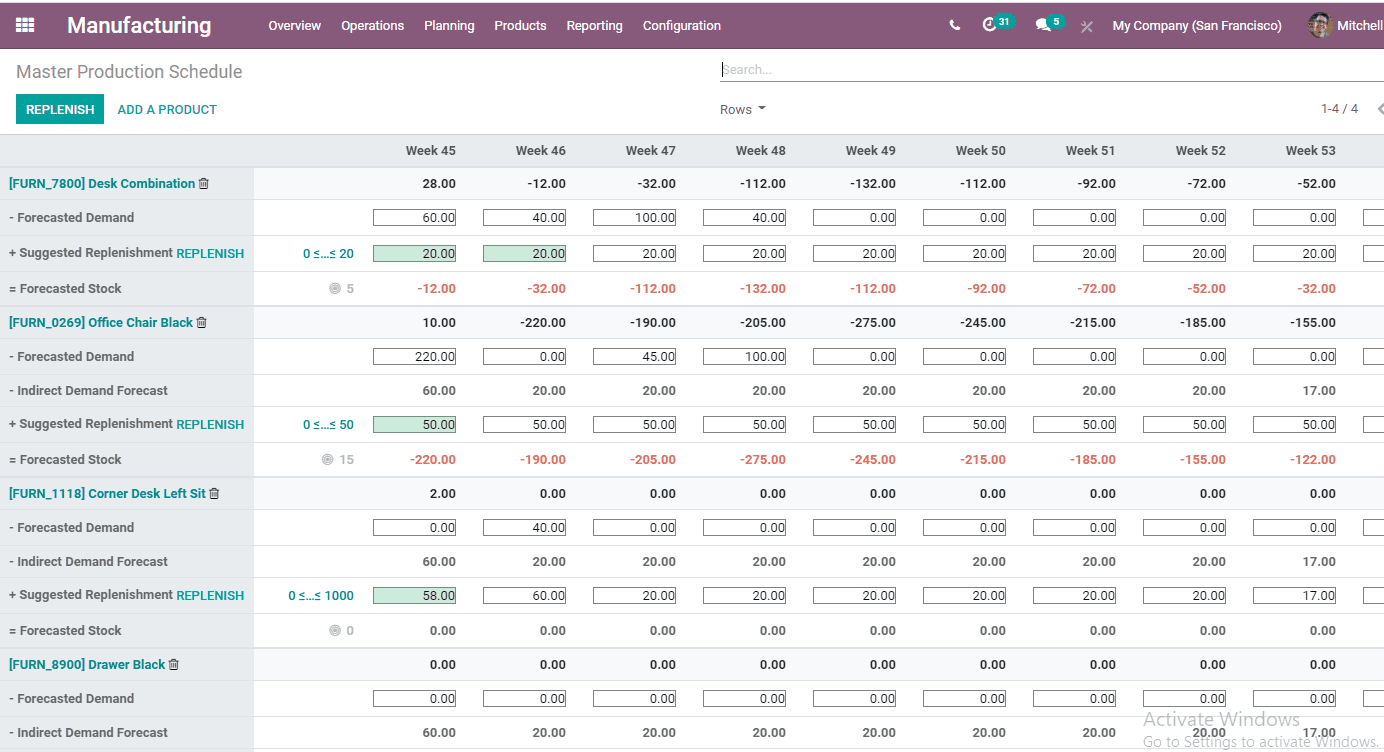

MPS also helps you decide the information that the user would like to display. The user can restrict the view by clicking on Row as given below. The user can check the boxes of the data you want to be displayed.

Estimate demand and launch replenishment

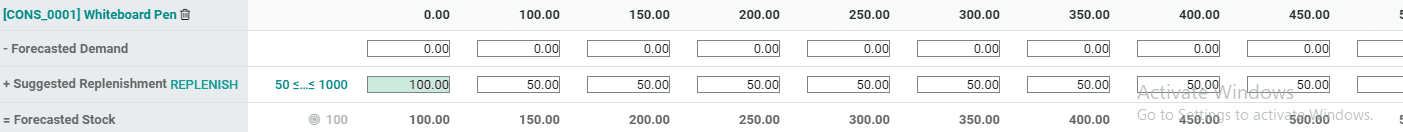

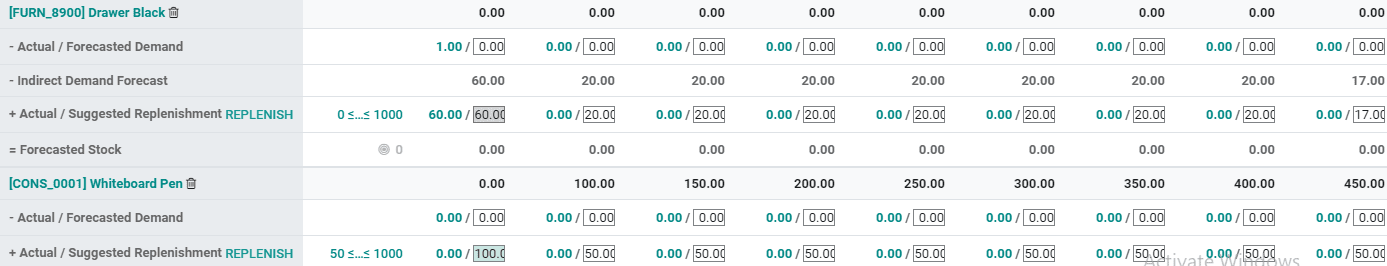

MPS helps a user to estimate demand for a particular product for a period of time. This detail can be included in the MPS as Demand Forecast. This feature helps the user to compare the forecasted demand with the actual demand. This process can be done at any time. The user will be able to forecast demand for a finished product. The demand for a finished product is directly proportionate to the demand for its components and the user from a manufacturing industry can make use of MPS to replenish raw materials.

MPS automates the calculation of quantity to be replenished at different periods. MPS also helps a business to do replenishments to be launched based on the vendor and manufacturing lead time. The replenishments will be displayed in green in MPS. A user can launch replenishment by clicking the Replenish Button

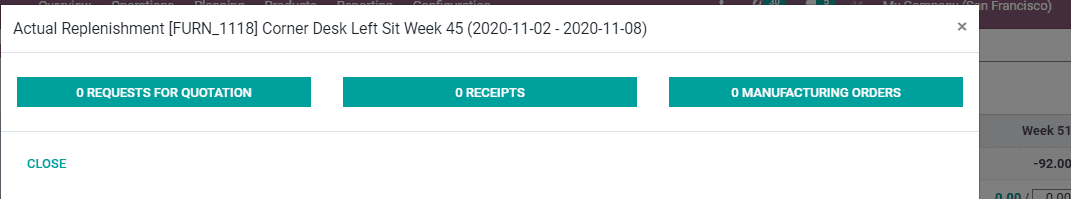

A user can select the option to replenish based on the configuration of the product. The user can either request for quotation, purchase or place manufacturing order to replenish. This can be accessed by clicking on the Actual Replenishment cell.

Cells colour significance

In Master Production schedule you can find different colours of cells. This colour indicates certain factors.

Green: This colour indicates the quantity of products to be replenished to reach the safety stock limit. This is computed based on the demand forecast and the indirect demand forecast.

Grey: Grey indicates that replenishment order has already been generated. It also means that the quantity of the product matches current data.

Red: Red colour indicates that replenishment order has been generated. Here, the quantity is very high considering the existing data.

Orange: This also means that the replenishment order has been generated. But Orange indicates that the quantity was very low considering the already available data

In MPS a Forecasted stock line may also contain red cells. Here, red which means the stock will be negative during the particular period.